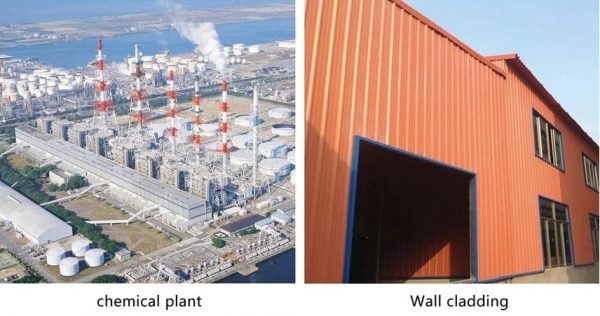

Anti-Corrosion Roof Sheet with Long Life Time for Chemical Plant

Zhongtuo New Material developed a type new material for Chemical Plant or the plants where are easy to be corrosion. After corrosion, the metal roofing sheets will be like this:

For those Chemical Plant building, now in the market they have two or three options, let us compare which type is better.

Option A: Use APVC ANTI-CORROSIVE COMPOSITE TILE

Option B: Use traditional PPGI or high quality metal roofing sheet

Option C: Use Zhongtuo new developed material.

Option A: Use APVC ANTI-CORROSIVE COMPOSITE TILE

Advantages of metal roofing sheet tiles:

Color steel tiles are double-sided spraying of thin steel plates, processed into various corrugations to give the thin plates good mechanical properties and serve as roof tiles. general

The color of the color steel tile is maintained for 5-10 years, and the service life is 10-15 years. Single-layer color steel tile-generally used in workshops and other heat and sound insulation requirements

Not high place. And if it is used in residential offices, color steel sandwich panels are generally used to enhance the effect of heat and sound insulation. Color steel plate machine

The mechanical performance is good, the span is large, the construction is convenient for irregular opening treatment, the appearance is beautiful, and the price is slightly higher. In addition, the color steel plate can be

With different plate thicknesses and different surface coating treatments, this is directly related to the mechanical properties and anti-corrosion durability of the color steel plate.

Prices also vary widely.

Disadvantages of metal roofing tiles:

1.No heat preservationand no heat insulation: Because there is no heat preservation layer, the heat and cold coefficient conduction of color steel tile is quite fast. In the day, the indoor temperature is high.

In winter, the indoor temperature also drops rapidly with climate changes.

2.Condensation: Especially in winter or hot weather, when the owner does not seal the doors and windows, the indoor air temperature is higher than the outdoor air

Temperature, the surface of the color steel tile will appear the phenomenon of condensation in the term of small water droplets. It is easy to cause the color steel tile to rust and corrode, shorten the service life,

It will also cause inconvenience to production.

3.Friends who have used color steel tiles know that color steel tiles-but after a long time of use, they will be bent, deformed and rusted condition.

UPVC ROOFING TILES Disadvantage:

1 High temperature resistance defects, everyone knows that synthetic resin tiles are co-extruded composites with PVC and ASA as the main materials. Both materials are

It can vulcanize itself and physically change at about 180 degrees. The product after cooling and molding is at 70-80 degrees.

The temperature will be deformed due to high temperature. Therefore, synthetic resin tiles are not suitable for smelting, casting, steel and other high-temperature building roofs watt.

2.Thermal expansion defect,when the temperature is between minus 30 degrees and 70 degrees, the interstitial structure of polyvinyl chloride molecules will be due to the contrast of high and low temperatures.

Dramatic and obvious changes occur, that is, thermal expansion and contraction. Therefore, the design of synthetic resin tiles has strict requirements on the spacing of the purlins to prevent synthesis

The resin tile sags or bulges due to thermal expansion and contraction! The waterproof effect is greatly reduced.

3.Not suitable for roofs with a slope of less than 15 degrees. Synthetic resin tiles are antique glazed tiles. This tile design tends to be beautiful and imitation.

In ancient times, the wave height of the flat arc-shaped wave peak was about 2.5cm, which could not meet the running water needs of the large-span building roof, so it is recommended to be larger.

For building roofs with spans and flat slopes, use synthetic resin tiles as the main roofing material. Of course, you can use some high-wave T-shaped tiles.

Use them together.

Now comes to Zhongtuo New Material Anti-corrosive metal roofing sheet building materials for Chemical plant:

What is that, how is the working principle?

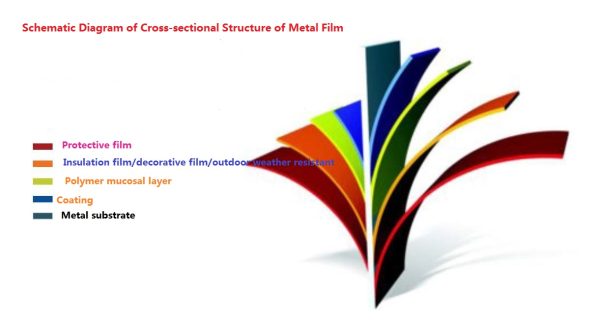

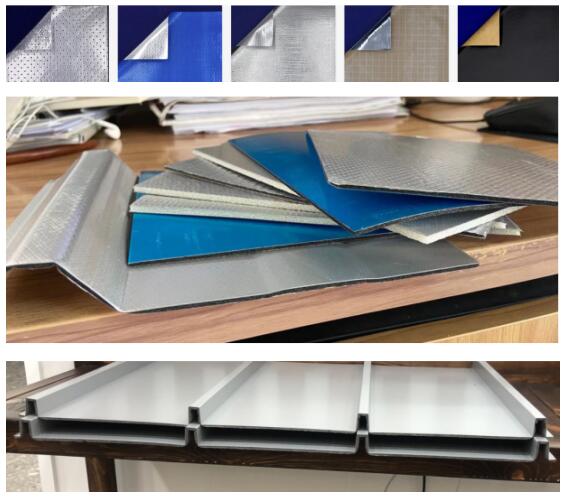

The new material is composed by 6 layers: Protection film +Aluminum foil+PPGI +PE Film (at the top)+Aluminum foil(at bottom layer )+Anti-corrosion layer

Corrosion-resistant alloy aluminum foil, modified polyester film, fluorocarbon coating and other materials are laminated to form an anti-corrosion composite material to achieve the performance characteristics of no rust and no water leakage. It can be used for more than 10 years in a corrosive environment, and the service life can reach 15 years or even more than 20 years in a normal environment, which greatly saves the maintenance cost in the later period!

Except the function of Anti-corrosive, it also has the other excellent features:

Related knowledge about ZHONGTUO NEW MATERIAL.

1.Length

We could customize the length for you.

The max length is 5800mm for 20'GP and 11800mm for 40'GP.

2.Color and color stable

Here are our common colors.

We could add ASA coating on the surface of roof sheet, this could keep the color unfading for at least 10 years.

It can maintain the stability of the color, even when exposed to harsh ,moisture,high and low temperatures all year-round.

3.Heat insulation

(1) The sunlight cannot go through our roof sheet

(3) It is better for heat insulation.

4.Fire proof:

It is difficult to be burned. The fire prevention level is B1.

5.Good water resistant:

Water can't pass through the PVC roof sheet.

We have special styles for area of heavy rain.

6.Corrosion resistant:

It is highly resistant against chemical corrosion of acid,alkali, etc. NEW MATERIAL roof sheet is good for chemical factory or acid rain area.