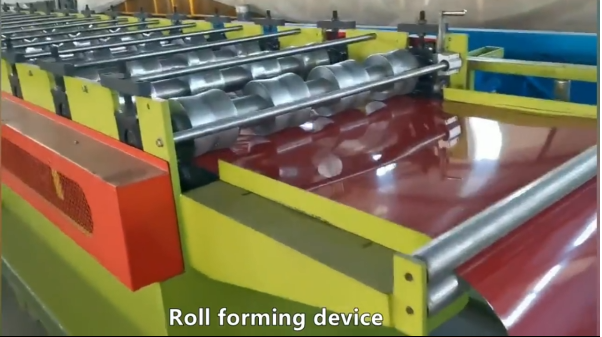

Double-Side Film Laminating Steel Production Line Laminating Machine

Fully Automatic Multi-Function PVC Pet Film Laminator Steel Laminating Machine for your specific needs. Applying the latest technology and experience. Get in touch now to learn more.

Double-Side Film Laminating Steel Production Line Laminating Machine Parameters

Place of Origin:Hebei, China

Brand Name:Zhongtuo

Condition:New

Video outgoing-inspection:Provide

Machinery Test Report:Provide

Marketing Type:Ordinary Product

Warranty of core components:2 years

Core Components:PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Voltage:220v

Power:15kw

Warranty:1 Year

Key Selling Points:Long Service Life

Product name:Hot Sale Steel Laminating Machine for Laminated Steel Sheets

Application:Metal filmed PE or Nano

Automation:Full automatic

Color:customized

Lace shearing glazed tile with anti-aging effect rolling forming machine

Lace shearing glazed tile with anti-aging effect rolling forming machine Lace shearing glazed tile with anti-aging effect rolling forming machine is designed to make the

Anti-aging wall cladding sheet rolling forming machine

Anti-aging wall cladding sheet rolling forming machine Types of Wall Claddings Wall claddings are available in several types and forms – from normal wooden panels to

High speed Anti-aging step tile rolling forming machine with stacker

High speed Anti-aging step tile rolling forming machine with stacker High speed Anti-aging step tile rolling forming machine with stacker is used to make the

Anti-aging IBR roofing sheet rolling machine

Anti-aging IBR roofing sheet rolling machine Generally speaking, an Anti-aging IBR roofing sheet rolling machine can easily produce the metal roofing sheets in the speed of the 25

Anti-aging step tile or glazed tile rolling forming machine

Anti-aging step tile or glazed tile rolling forming machine Anti-aging step tile or glazed tile rolling forming machine is designed to produced the metal step

Anti-aging Corrugated Sheet rolling forming Machine

Anti-aging Corrugated Sheet rolling forming Machine Anti-aging Corrugated Sheet rolling forming Machine typically includes the following components. Manual decoiler Feeding guide Roll forming system Transmission system

Supply Ability

30 Set/Sets per Month Hot Sale Steel Laminating Machine for Laminated Steel Sheets

Double-Side Film Laminating Steel Production Line Laminating Machine

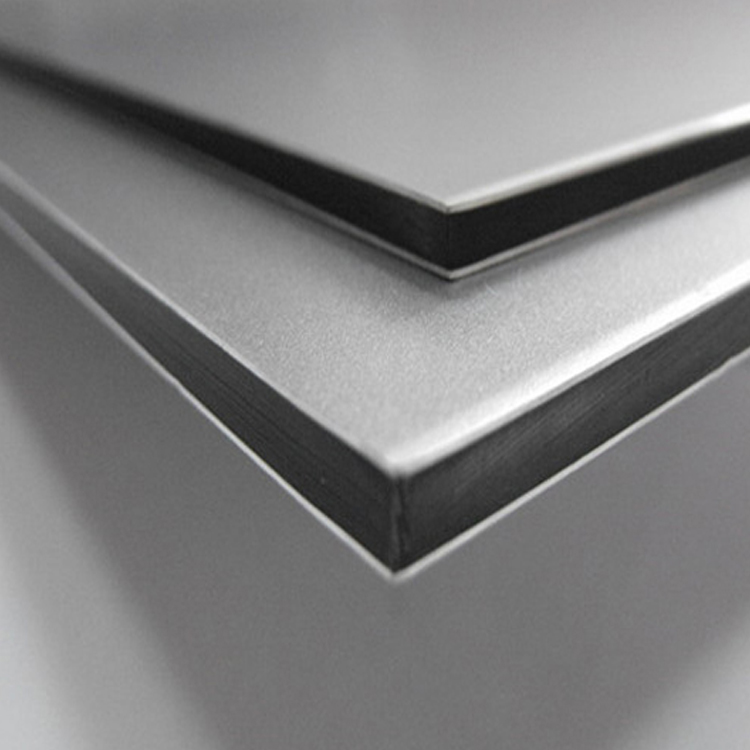

This machine is suitable for composite of color steel coil with PET color aluminum film, pure aluminum film, PVDF, ASA, PVC film (plastic steel roofing tile), stainless steel with color film (home appliances, door plate). Humanized design, advanced technology, this machine with cantilever winding, lifting sports car, alignment device, winding high precision alignment device, save both time and labour.

Super long material storage rack, realize rewinding without stopping. High-power seam welding machine, shear machine, alkali washing tank, clean water tank. It caused rapid aging of products because of large heat loss and poor thermal stability of oven. This machine adopts no oven heating which low heat loss, strong stability, fast production speed, reliable fastness. The whole production line of this machine is automatic constant tension, saving manpower and time. Double-side film-lamination at the same time , single – sided embossing, concave embossing are all available.

Double-Side Film Laminating Steel Production Line process

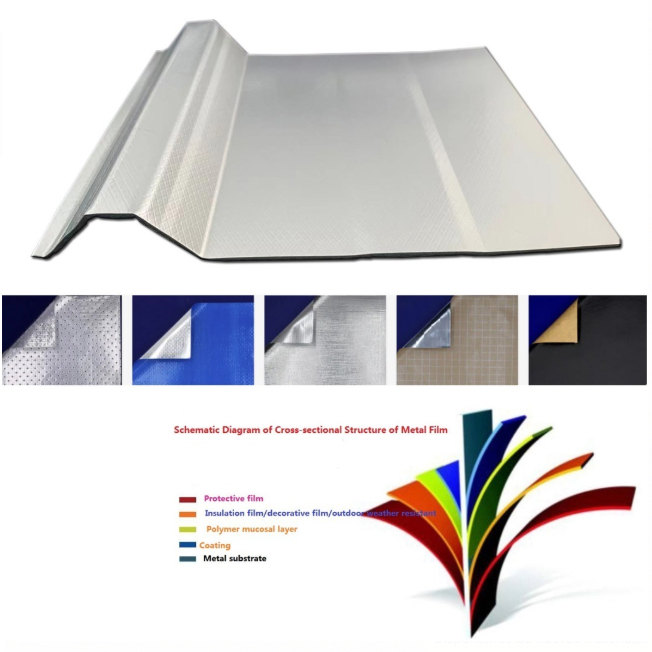

Adopt plastic film(PET,PVC,PVDF,ASA) combined with metal plate through hot melting, which has solved the corrosivity of metal plate and metal container, both has the decorating, barrier of plastic film and the malleability, figurability of metal sheet.

Metal plate: galvanized sheet, Stainless Steel sheet,Cold Rolled Sheet,Aluminum Sheet.

Plastic film:PET, PVC,PVCF,ASA etc.

Film color:RAL Color/Pantone Color;Wood Grain,Marble Grain,Brick Grain,Stone Grain,Flower Pattern,Brushed,Embossed

Double-Side Film Laminating Steel Production Line Laminating Machine

material | composite panels:metal material coil /sheet as basic material,and can filmed leathers,PE,PVC,or Nano,etc |

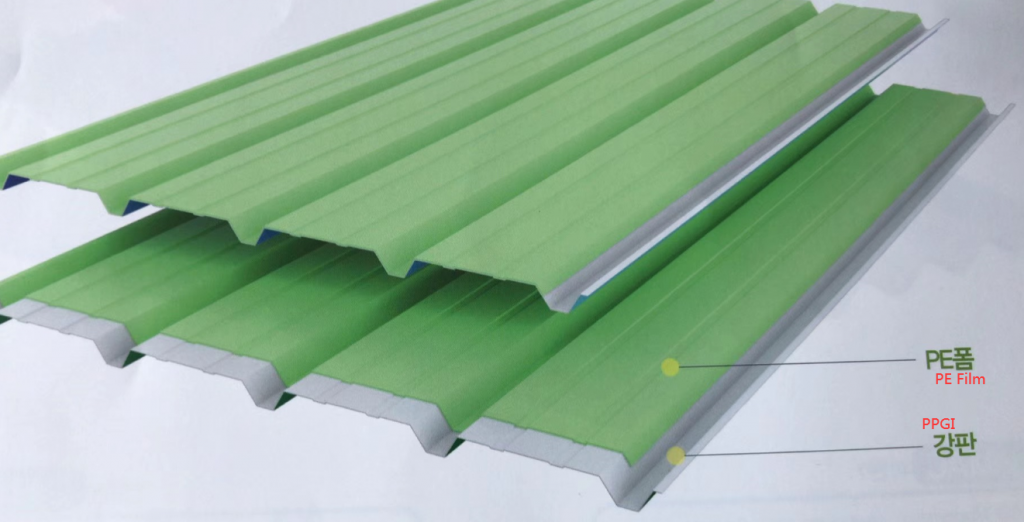

hot sale layers | 2 layers(metal coil filmed PE or leather for anti-condensation roof sheet) |

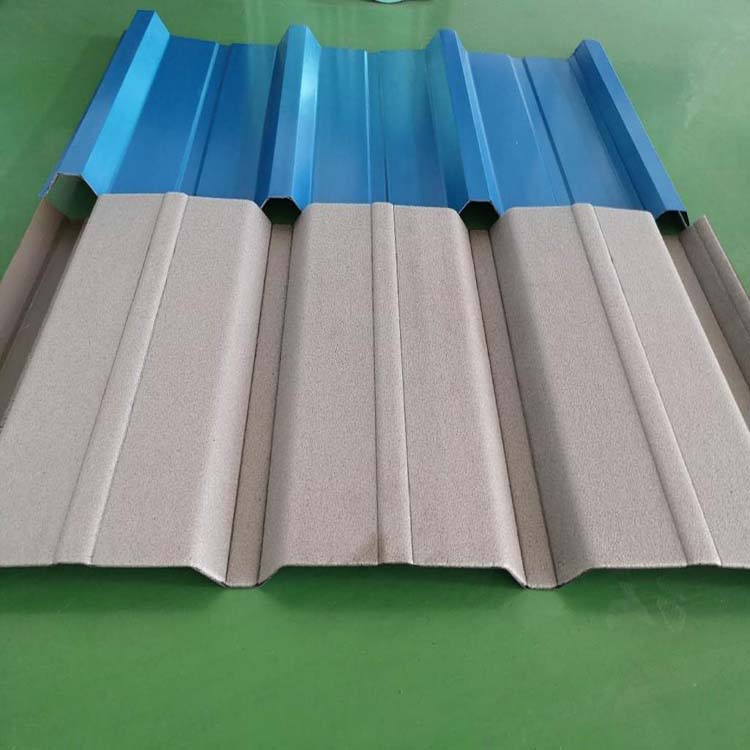

6 or 8 layers: Anti-aging transparent layer-aluminum foil-polymer film (substrate)-polymer film-foam layer-polymer film-aluminum | |

advantages | anti-condensation/raindrop/waterproof |

sound insulation | |

heat insulation/thermal insulation | |

acid resistant/acid-proof | |

Alkali resistance |

2 layer type finished products showing

6 or 8 layers type finished products showing

foil-anti-corrosion layer,compared to the 2 layer type,can anti-corrosion.

Why Choose Us